In-line full inspection coverage

- dic@dynamite.com.tw

- 03-3715899

OMRON VT-X750

OMRON VT-X750

High-speed automated X-ray CT inspection system

In-line Full Inspection System

CONTACTlast update: October 23, 2017

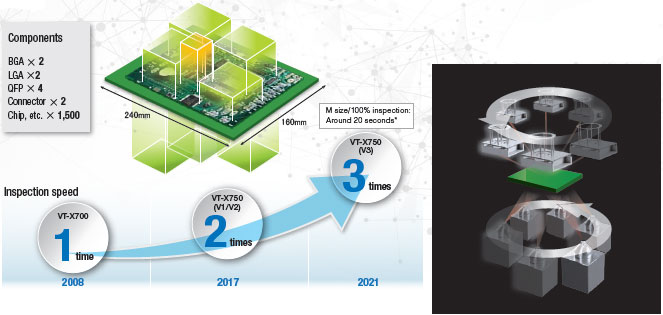

The VT-X750 improves upon previous Omron 3D-CT technology making it the fastest X-Ray inspection system to date *1.

The automated inspection logic has been improved for many parts such as IC heal fillets, stacked devices (PoP), through hole components, press-fit connectors, and other bottom terminated parts.

Increasing automated inspection speed and expanding inspection logic enables full, in-line inspection coverage by 3D-CT method.

*1. By an internal investigation in October, 2017.

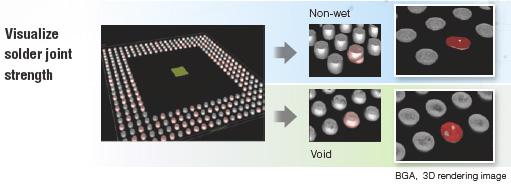

Visualize solder joint strength

OMRON’s unique 3D-CT reconstruction algorithms provide excellent solder shape recognition and defect detection.

Quantitative analysis allows for an automated inspection process which minimizes the risk of escapes while providing fast and repeatable operation.

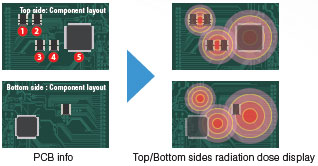

Design constraint free

Dense and dual sided board design can provide challenges for X-Ray inspection.

However, Omron's 3D-CT technology can overcome such design restraints.

Reduce radiation exposure

High speed imaging technology

The VT-X750 provides the shortest X-ray exposure time without sacrificing inspection image quality.

X-ray source at the bottom

By locating the X-ray source under the board, both exposure and dosage is physically reduced to the more important devices mounted on the top.

Low energy-cut filter

Standard equipped filter reduces X-ray exposure further minimizing damage concerns to memory products.

Operation safety

Ultratrace leakage dose

Exposure dosage to operator is less than 0.18 mSv *2 per a year. This is less than one-tenth compared with that from natural environment.

*2. Teaching operation for one hour per day.0.5μSv/h x 1h/day x 365days = 0.183mSv

OMRON’s safety components

The VT-X750 complies with CE, SEMI S2/S8 and other safety standards by utilizing OMRON’s latest generation of safety controller and light curtain products.

X-ray shielding box, made in Japan

The machine shielding quality is ensured through three surveys (twice at the factory in Japan and once on site).

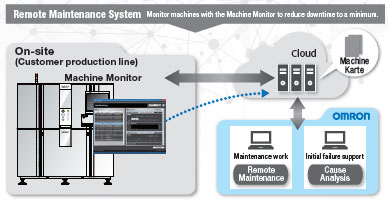

Zero down time

To achieve “Zero down time” during the SMT production process, OMRON supports machine operation globally by preventative maintenance, emergency support and machine monitor with remote access.

Remote Support

Monitor the machine's status and eliminate production down time.

Global Support

More than 30 locations.