- dic@dynamite.com.tw

- 03-3715899

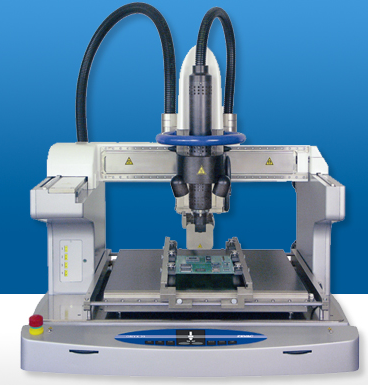

AirVac ONYX29

High Performance Automation Rework

Robotic SMT Production, Rework & Assembly

Lead-Free Requirements

Seven Axes of High Automation

Multiple Field of View (MFOV)

Automated Precision Component Pick-Up

|

主要优点:

|

|

| 特点与优势: 无铅要求 •强大的2000瓦顶部加热器。 红外(IR)底部加热技术。加热元件在整个表面上提供非常均匀的预热。底部加热面板是19“×19”,并具有四个(4)独立可编程加热区(6000瓦)。 •可编程的冷空气喷射和线性气刀提供精确的冷却控制,优化回流焊时间。 •交互式温度曲线分析提供“即时”调整。 高自动化七轴 •控制X,Y,Z,Theta,视觉变焦,视觉X和视觉Y. 多视野(MFOV) •自动将相机索引至最大75mm的大型组件的四角。 自动精密部件拾取 •从大,小华夫饼托盘,凝胶包装,磁带和卷轴,以及单组件嵌套的多位置拣选功能。 •精密微力传感提供了拾取微小,脆弱设备所需的非常低的力量。 点胶技术 •新兴技术的返修和小批量组装通常需要集成精密分配锡膏,助焊剂,环氧树脂或底部填充料。 |

|

专有的非接触式现场清洁

|

|

OPTIONS High Throughput Carousel Fixture for Small Board Rework #0029.15.041

|

Automatic Tool Changer with Component Pick, Prep & Drop

|

| Site Cleaning System #0029.03.012 • Includes Standard and Micro nozzles. • High temperature composite vacuum tip eliminates metal-to-metal contact. • Vacuum sensor automatically and continuously adjusts tip height, providing non-contact site cleaning. • Various size heating noses and tips to clean virtually any site. • Ready-to-use site cleaning programs for fully automated solder removal. |

|

| Micro Component Rework & Site Cleaning Kits Precision Rework in Four Simple Steps! • Removal, Site Clean, Apply Solder Paste, and Component Replacement • Kits available for various Ultra Micro and Micro Components • Component specific Micro Tips for precision process operations |

|

| Component Shuttle #0029.02.042 • Provides a safe, repeatable location for component pick up, flux dipping and drop off away from the heated work area. • Eliminates manual component loading/removal in the heated work area. • Software-controlled pneumatic shuttle enters the work area for pick up, flux dipping or drop off, then exits the work area. • Shuttle-based component pick up and flux dipping is set and monitored with machine force placement system. • Multi-location pick and flux dipping capability for multi-processing of small devices (custom tooling required). |

|

|||

| Direct View Camera with 20" Video Monitor #0029.04.041 • Provides high magnification site viewing including the ability to verify when component reflow has occurred. • Operator is instructed to position the camera on the site. Focus, zoom, and lighting adjustments are made to optimize clarity. The image is displayed on a flat screen monitor. • A process development aid especially for difficult to see tiny solder joints. • Recommended for use in conjunction with the automatic site cleaning system to verify cleaning on dense assemblies and for the dispensing option to provide dispense inspection capability. |

|

|||

| Dispensing System #0029.08.010 • Provides on-machine dispensing of flux, solder paste, adhesive, epoxy or underfill. • Proprietary time/pressure dispenser features automatic pressure compensation and programmable vacuum adjustment for accurate and repeatable results. • Uses precision DL Technology dispense needles. • Automatic pattern generation software to easily create dispensing patterns • Note: dispensing requires ambient machine/ assembly temperature. Nozzle cool air injection and the board cooling system can be simultaneously activated to prepare the machine and assembly for dispensing, however this in not practical from a time standpoint for each individual rework process. • The on-machine dispense option is typically used in either a batch mode or for low volume, specialty applications. |

|

|||

| Dipping Kit for Solder Paste or Flux #FASET1 • Superior to applying paste via component or board stencils • Easier process, less operator involvement than stencils (consistent results) • No component or board/pad coplanarity preparation issues • No adjacent interference issues • Excellent for extremely fine pitch, sphere or leaded size components • One set of dipping pedestals replaces dozens of custom component stencils |

|

|||

| Ergonomic Workstation with CPU Holder #1003.05.010 Monitor Stand Option for Workstation #1003.05.005 Nozzle Stand Option for Workstation #1003.05.006 Locking Drawer Option for Workstation #1003.05.007 • Workstaton provides a self contained work cell environment for the machine and operator. Dimensions are 60"W X 36"D. Very sturdy construction with anti-static laminate surface. (Workstation includes CPU holder, everything else is an add on option). |

|

|||

| Universal Insertion Tool #AU6LGA47R • Mechanically self-centers any device for accurate pick-up. Used in conjunction with the automatic component shuttle. |

|

|||

70mm (2.75") Topside Clearance #0029.01.052(standard is 30mm) • Provides increased top side clearance for assemblies with vertical daughter cards or tall devices that exceed the standard 30mm (1.2”) top side clearance. Fume Extraction Manifold #300.00.547 • Removes flux vapors for operator health and safety. • Includes fume extraction manifold and hose assembly. • Requires connection to a central exhaust or self-contained filtering system. Four Additional Thermocouple Ports #300.00.504 Thermocouple Organizer #0024.90.047 |

|

|